Integrated Inventory Management System for Vehicle Parts in Milan, Italy, and Distribution Company in Melbourne, Australia

In this case study, we explore the implementation of an integrated inventory management system for a vehicle parts supplier based in Milan, Italy, and a distribution company located in Melbourne, Australia. Both companies collaborated to streamline their supply chain operations, optimize inventory management, and enhance overall efficiency.

Client Background

-

-

- Milan-Based Vehicle Parts Supplier: A well-established company in Milan, Italy, specializing in the distribution of vehicle parts to a wide range of customers, including automotive repair shops and retailers.

- Melbourne-Based Distribution Company: A distribution company located in Melbourne, Australia, focusing on the import and distribution of vehicle parts sourced from various suppliers, including the Milan-based supplier.

-

Challenges

The Milan-based vehicle parts supplier and the Melbourne-based distribution company faced several challenges before the implementation of the integrated inventory management system:- Inventory Discrepancies: Both companies experienced inventory discrepancies due to manual data entry errors and a lack of real-time inventory visibility.

- Communication Gaps: Inefficient communication channels led to delays in order processing, resulting in occasional stockouts and excess inventory.

- Order Management: The manual order management process was time-consuming and prone to errors, impacting customer satisfaction.

- Forecasting: Accurate demand forecasting was challenging, leading to overstocking or understocking of critical vehicle parts.

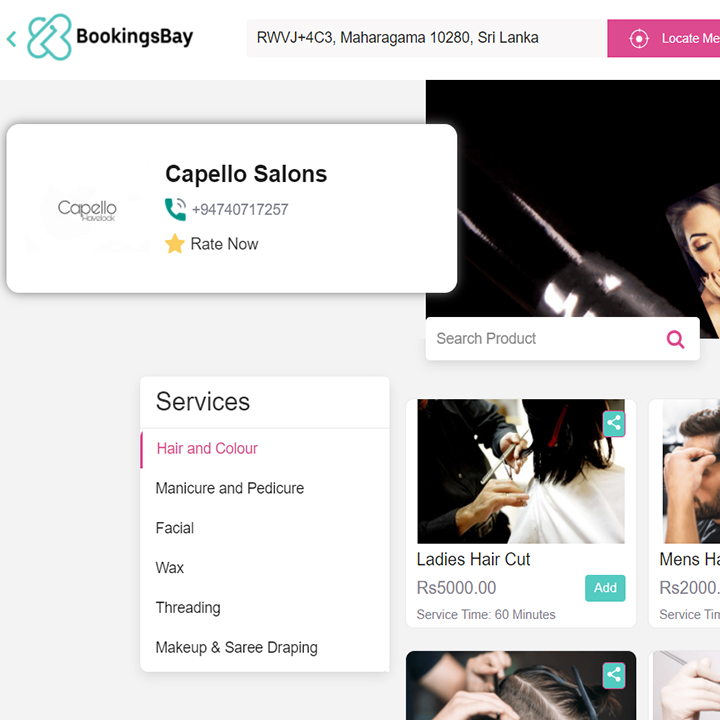

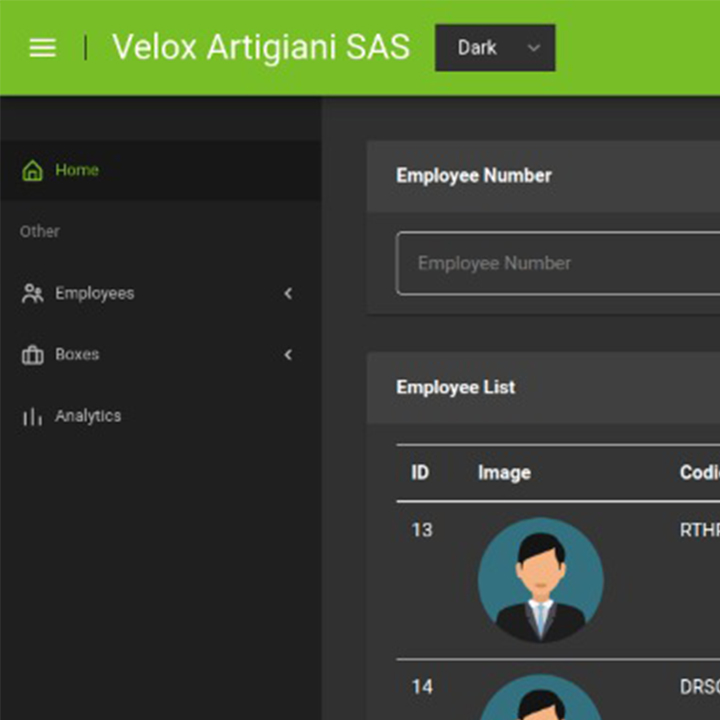

Solution

The solution involved implementing an integrated inventory management system that connected the Milan-based supplier and the Melbourne-based distribution company. The system offered the following key features-

-

- Real-time Inventory Tracking: The system provided real-time visibility into inventory levels, enabling both companies to monitor stock quantities accurately.

- Automated Order Processing: Orders were automatically generated based on predefined reorder points and historical demand data, reducing manual intervention.

- Supplier Integration: The Milan-based supplier’s inventory and pricing information were directly integrated into the system, allowing the Melbourne-based distributor to access up-to-date data.

- Demand Forecasting: Advanced demand forecasting algorithms helped in optimizing inventory levels and preventing stockouts or overstocking.

- Barcode Scanning: The system supported barcode scanning for incoming and outgoing shipments, ensuring accurate inventory counts and reducing errors. Custom Reports: The integrated system generated custom reports, including inventory turnover rates, order fulfillment status, and sales trends, aiding in decision-making.

-

Results

The implementation of the integrated inventory management system yielded significant benefits for both companies:- Inventory Accuracy: Real-time inventory tracking reduced discrepancies and improved stock accuracy.

- Efficient Order Processing: Automated order generation streamlined order management and reduced lead times.

- Improved Communication: Enhanced communication between the Milan supplier and Melbourne distributor resulted in better collaboration.

- Optimized Inventory: Demand forecasting and automated reorder points helped maintain optimal inventory levels, reducing carrying costs.

- Reduced Errors: Barcode scanning minimized errors in inventory counts and order fulfillment.

- Enhanced Customer Satisfaction: Faster order processing and reduced stockouts improved customer satisfaction levels.